Most people laughed at Nick Leason’s idea of a surfboard that could fly above water.

Now, nine years later, Leason’s Puerto Rico–based company is on pace to double its 2021 sales of the once-scoffed-at pipe dream for riders like Ellen DeGeneres and Mark Zuckerberg—and stocked in over 300 affiliate shops worldwide.

The company, Lift Foils, led by Leason as CEO, created the first commercial eFoil. An electronic hydrofoil, or eFoil— is a battery-powered surfboard that elevates a rider over the water at up to 35 mph for 100 minutes at a time. Lift is growing fast and it’s the global market leader in the eFoil business. The Puerto Rican company has doubled its sales every year, and owns a 65% market share of the global eFoil market. But Leason’s eFoils haven’t always dominated the industry. In-family conflict, a burned-down factory, and constant trial and error encapsulate his journey—one built from the ground up, literally, in order to fly.

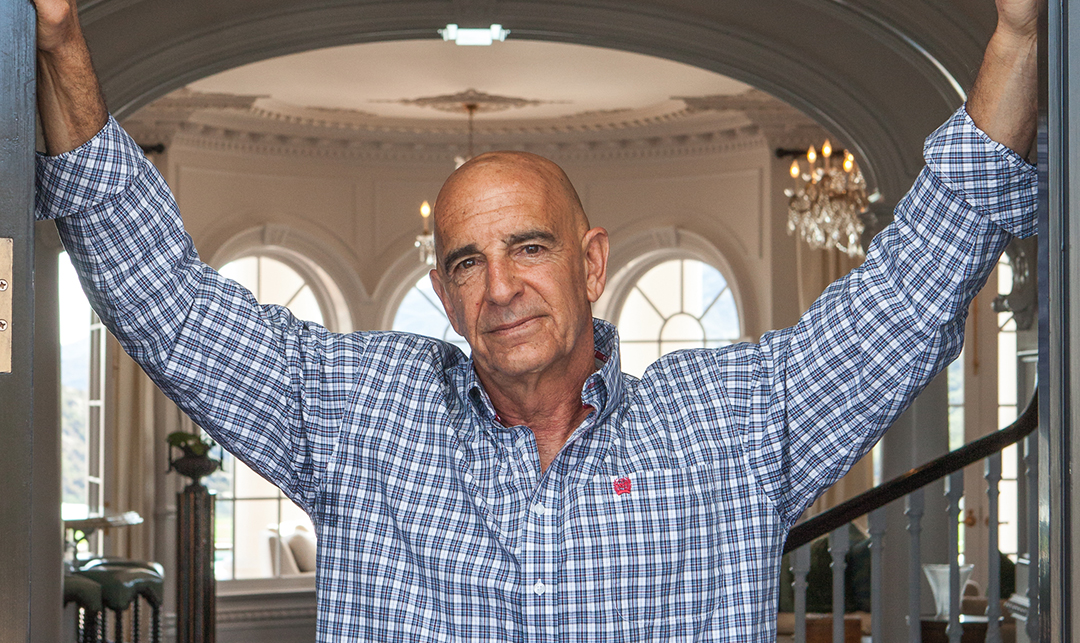

Nick (pictured right) and his father Mike (pictured left)

FATHER-SON FOUNDATION

Leason has always loved surfing. He’s also fascinated by flight. He went to college in the U.S. for mechanical engineering but afterward returned to his home country, Puerto Rico, to build surfboards with his father.

They built a 5,000-square-foot factory in their backyard to make surfboards and paddleboards, reconstructing an old government industrial building with help from Leason’s father’s construction crew. Leason’s father had been in the manufacturing business with Leason’s grandfather for decades in Puerto Rico and, like Leason, was a surfer.

Still, he thought his son should be doing something else with his life.

“It was like a bit of a project, but he didn’t really want me to get into that,” Leason says. “He wanted me to go and work in bigger and better industries or places. You know, we were just building surfboards. He’s like, ‘No, you can’t be a surfboard builder.’ But for me, I was into it, like, ‘Let’s roll, we’ll build something.’”

The surfboard-crafting rolled on despite Leason’s father’s trepidation. The surfboard and paddleboard production was also powered by engineers, whom Leason said aren’t difficult to find in Puerto Rico, noting that there are many American-born and Puerto Rican engineers who move to and stay on the island and work on aerospace technology.

The shop-floor production was run by no-nonsense, self-sufficient crew who, without a demand from Leason, preferred to start working at the crack of dawn—the kinds of people who will fix an electrical grid right after a hurricane blows it away, Leason says.

Along the way, while tinkering with 3-D shapes on surfboards and paddleboards, Leason and his engineers discovered the hydrofoil—the mechanism that lifts a board over the water’s surface via a “foil” attached below it, the backbone of eFoil technology—in kite surfing prototypes.

Laird Hamilton, a famed big-wave surfer from Hawaii, was already experimenting with aluminum hydrofoils, strapping his feet in with snowboard boots to reach higher speeds riding a wave. Leason says it looked dangerous and it got him thinking about how to adapt the technology for him.

Then, someone else constructed a carbon-fiber hydrofoil for kitesurfing, which got more people on the water than Hamilton’s hydrofoil.

One of those people was Leason. While his ride was “pretty rough,” he felt a hunch.

“It’s pretty addicting; it really makes your mind spin,” Leason says. “I was like, ‘Man, this is awesome. Hydrofoils, it’s everything I love: It’s composites, it’s hydrodynamics, it’s surfing, it’s flying. I need to build one of these.’”

Leason realized his passions could intertwine, and began obsessing over making a surfboard fly.

The LIFT3 Foil

‘I TOLD YOU’

Leason’s crew still built paddleboards, many of which catalyzed victories in races across the U.S., but Leason began constructing hydrofoils on the side.

Some people thought he was going somewhere with his hydrofoils, while others in the surfing community were skeptical.

“I’d take my paddleboards and my hydrofoils to the Surf Expo”—a watersports and beach-lifestyle trade show—“and everybody else in the industry would just laugh at me,” Leason says. “They were just like, ‘That’s never going anywhere.’ And I was like, ‘Oh, I’ll show you.’”

When Leason was in China sourcing suppliers to help craft the eFoil, a left-on vacuum pump burned down his entire factory. However, he says it allowed him to solely focus on eFoil developing with paddleboard crafting out of the picture.

“It’s not over. It’s just a new beginning—good riddance,” Leason says. “That was a blessing because the other, that artistic little business [making paddleboards] was dragging me down and just taking all of our energy and it didn’t allow us to really focus on what was more important. So, I just said, ‘Alright, that business is done, and I’m going to focus on this product,’ and everything went quiet and it allowed us the time necessary to build what we had to build.”

Then came the work—“years and years and years and years,” Leason says. Those years also consisted of Leason persistently showcasing hydrofoils at the Surf Expo, until he realized he should branch out.

He eventually saw what other surfers didn’t in hydrofoil technology: that its reach could expand beyond the surfing world. Most people at the time thought hydrofoiling was exclusive to Laird Hamilton types who rode 50-foot waves, which turned off a sizable portion of would-be users.

“There are so many more people in the world that are not surfers, then there are surfers, and there are a lot of people that are on bodies of water, be it an ocean, a lake, or a river. There’s just a ton of people that are out enjoying the water,” Leason says. “So, it totally opened up our demographic. … We just completely broke away from the surf industry. Not to say that we don’t include [surfers], we have that demographic of people and they enjoy that too, but we’re not limited to that demographic at all.”

The work became convincing people outside of surfing that hydrofoils have an audience beyond watersport daredevils. Getting insight from friends in other industries helped Leason conceive hydrofoils’ potential.

With a larger demographic in mind, he kept at it. Seven-day—and sometimes night—workweeks brought perpetual trying and failing. He and his engineers didn’t know what they were getting themselves into, he says, but they learned something new at every turn. One was how sophisticated hydrofoils are, that they can’t just slap a motor on and call it an eFoil.

Another lesson, Leason says, was how expensive hydrofoil production was. He didn’t know what price would justify it. Before he took his best guess, Leason knew he had to garner pre-release hype after seeing motorized surfboards being developed for decades but never striking gold on the market—they either had the wrong presentation or product, or prolonged “coming soon” or “pre-order now” website notices.

So, to Leason, introducing his hydrofoils properly meant showcasing the “magic” of them in a video. It was shot in the right place, with the right people, who found the right camera angles, Leason says.

The video garnered 100 million views. Leason began putting his hydrofoils on the market.

“I thought I’d sell it at $6,000,” Leason says, “and then I get it, you know what, might have to be $8,000. My old man’s going like, ‘Ah, you’re crazy.’ And then at one point, I said it’s $12,000. ‘Oh, you’re absolutely nuts, nobody’s gonna buy a single one of those things.’ I’m like, ‘We’ll see, we’ll see.’”

“We put it out there, and sure enough, the day we launched it, we had that little Shopify app, it was going to ‘ching ching ching ching,’ people were ordering up. We had like 50 [orders] right off the bat. I was like, ‘I told you that they want it.’”

Customers were charged $2,500 deposits before Leason, with his father in his ear who said it costs more than that to build, increased it to $6,000. Lift Foils launched its first commercial product to customers in 2018, one year behind schedule, but Leason didn’t mind the wait. Neither did the buyers.

Nick and his father Mike

RELATIONSHIPS THAT RECIPROCATE

Leason’s appeal to non-surfers panned out. He says his eFoils’ price point isn’t intended to be a barrier to entry—Lift Foil’s Full Range LIFT3 EFOIL goes for just under $12,500, which Leason says is in line with some pedal-assist bikes. Their new LIFT3 F model starts even lower, just under $10,000. Beginners can be up and riding an eFoil in 20 minutes.

The ease of riding has also brought Lift Foil repeat customers, Leason says. Lift Foils takes special care of them: The company will replace accidentally broken eFoil parts for discounts and provide one- to two-year warranties. Usually, he says, the generosity is reciprocated—customers will buy more products, which ends up paying for the warranties and replacements.

Lift Foils uses an affiliate system to bring in even more riders. If someone tells Lift Foils they’re tired of their day job and want to live by the beach and give eFoil lessons, Lift Foils will give them the boards for their shop to sell and commission for every person who buys eFoils after a lesson. If the rider wants more time to weigh whether spending $13,000 is worth it, Leason says, they “demo” ride an eFoil for a day.

The over 300 Lift Foil affiliates span much of the U.S. and many international locations, including recently all six Sandals Resorts in Jamaica and Habitas in Bacalar, Mexico. Still, Leason says, there’s room for Lift Foil to expand. He wants to tap into Texas and the Midwest more, where there are “big houses on the lakes, big American flags, and two cars in the garage.”

But what is enjoyable to Leason, and what he thinks is the future, is what’s flown Lift Foils out of a scorched factory and into the hands of about 8,500 people so far this year.

“What we put together is so much cleaner and easier and more efficient and more fun than what’s currently out there in the market,” Leason says. “You’re gonna see more and more and more people zipping around on these little devices, just having a blast, versus a huge device that’s like, ‘I don’t even know where to store the damn thing.’ … I’m excited—too excited.”